Harnessing secondary raw materials from silicon photovoltaic production

Assessment of waste and by-products for the optimisation of manufacturing processes

In the EU ICARUS Horizon project (grant agreement No. 958365), 17 partners coordinated by Sintef, Norway, are working on eco-efficient refining pathways for secondary raw materials from the production of silicon ingots and wafers, in order to develop them for high-quality markets.

ICARUS supports the expected European growth in the necessary recovery of high-quality silicon-based secondary raw materials and the auxiliary substances used by optimised treatment pathways. The process waste which is, for example, rich in high-purity silicon and is characterised by high energy consumption in production, is converted into high-quality secondary raw materials for various industrial applications.

Harvesting secondary raw material potential

The wafer production process is very energy-intensive and produces waste streams that still contain a substantial quantity of silicon and other valuable substances such as graphite. Harvesting this secondary raw material potential reduces the European dependency on imports and the costs of an improved environmental performance.

Within the scope of the ICARUS project, bifa is responsible for the topic of waste assessment. To this end, available information is collected on the input and output substances and the waste-producing process itself.

The information about by-products and waste and their specific properties are then each assessed to determine whether they are a by-product or waste and whether hazardous properties exist or not. The results are also used to optimise the manufacturing processes.

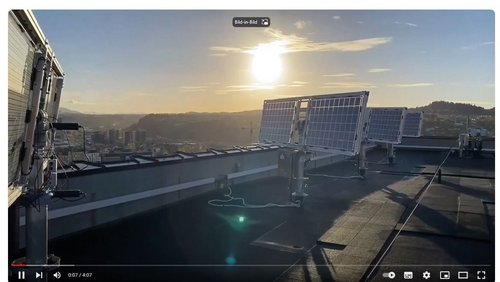

The bifa approach is shown in the video using the example of the waste stream of high-quality graphite.