Recovering precious and special metals - Founding Projekt

Special metals such as rare-earth metals (rare earths) or Indium are not recovered from post-consumer waste, or only to a very limited extent.

Many products that contain such metals have only recently appeared on the market. The returned quantities are still too small and large-scale recycling methods have not been implemented.

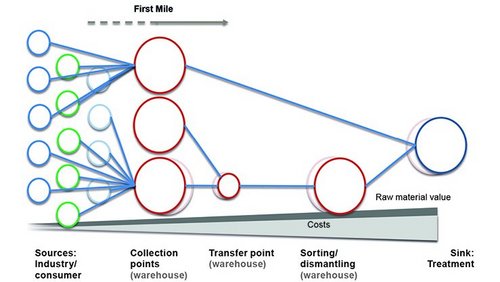

Precious metals, on the other hand, have long since been recovered. However, their collection and separation from low-concentration waste streams of many small sources is a challenge. The concentration or quantity of precious and special metals in waste products or components is also frequently so small, that their collection or separation is currently not economically viable.

Can new logistics concepts and approaches to intelligent organisation and arrangement of material and information flows help? What technical, organisational and legal options can be created for longer-term interim storage until large-scale recycling processes are available? Together with HSAOps at Augsburg University of Applied Sciences and the law firm avocado, bifa Umweltinstitut examined these questions on behalf of the Federal Environment Agency (UBA). Examination focused on the following waste streams: NdFeB magnets, vehicle electronics, environmental catalytic converters containing precious metals, waste streams containing cerium and lanthanum, fluorescent substances containing rare-earth metals, LCD layers containing indium and tantalum capacitors. Finally, ways of estimating ecologically optimal recovery yields were worked up and proposed measures were developed and assessed.

The appropriateness of elaborate legislative measures is evaluated critically in view of the small potential quantities and the expected losses along the recovery chain. An increase in returned quantities of properly collected waste products would be beneficial. Recycling enterprise resource planning systems, workshops on the consolidation of small scale logistical activities or strengthening lean management in smaller dismantling companies could improve the economic viability.

![[Translate to Englisch:] Placeholder](/fileadmin/_processed_/e/b/csm_Header_Projekte_603d83e502.jpg)