Life cycle analysis of new ultrahard materials - EU Research project

Within the project, new types of alternative material solutions based on tungsten carbine/cobalt and polycrystalline diamond/cobalt were developed for increasing the lives and possible substitution of the critical raw materials tungsten and cobalt in tools for metalworking and stone machining

The project was coordinated by the University of Lund (S) with support from Boukje.com (NL). Other partners, apart from bifa Umweltinstitut GmbH and the TU Bergakademie Freiberg (D) were the V.Bakul Institute for Superhard Materials (ISM) (UA), CRNS (F), and the industrial partners Sandvik, SECO Tools (S) und Element Six (GB). The developments included the production of the new materials, their integration in tools and testing them in metalworking and stone machining under extreme conditions. bifa examined the potential environmental aspects for the new materials in production, use and recycling and combined the results with performance and cost data of Lund University to produce an ecoefficiency portfolio.

In the project, numerous new material combinations were produced and tested on the basis of diamond and cubic boron nitride, as well as new types of superhard phases. Particular attention was also paid to the achievable performance and the costs, as well as an in-depth understanding of the underlying microstructures, tool geometries and resulting wear mechanisms.

With the continuous delivery of data by all partners, a life-cycle model was created for the materials and energy and was updated in line with the respective project progress. Missing data were taken from the literature or databases. The following two routes were considered:

> Sintering of cutting tools based on hard metal with protective coatings and

> combined production methods by sintering hard metal blanks combined with soldered on superhard cutting inserts, which are generated using high-pressure high-temperature methods

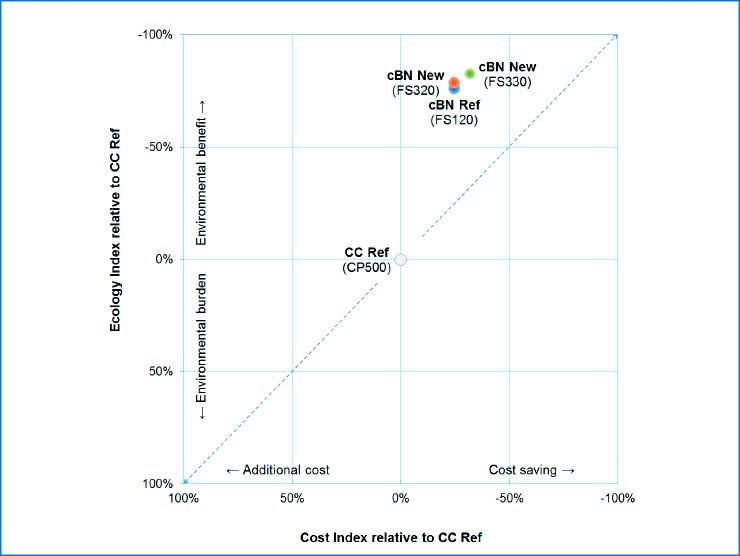

Due to the optimised materials, better machining results and longer lives were achieved by the new tools. The new products are up to 80 % more environmentally friendly and save up to around 25 % costs. The exemplary figure, in the top right below the bisecting lines of the angles, shows the new materials in relation to the reference material with their clear cost-cutting potential and higher environmental compatibility in the case of metalworking. The largest hurdles on the way to new industrial products are thus largely overcome.

The project was funded by the EU under ID 689279 as part of the Horizon 2020 research and innovation programme.

![[Translate to Englisch:] Placeholder](/fileadmin/_processed_/e/b/csm_Header_Projekte_603d83e502.jpg)